Digital automatic coupling for freight transport

Digital automatic coupling (DAC) for freight transport is one of many emerging innovations aimed at harmonizing the European rail system. Combined with ERTMS1 and other emerging technologies, DAC promises to revolutionize the rail freight industry. Here’s how it works.

Today’s system

The European railway system is unique. While the United States, Russia, China and many other countries use an automated mechanical coupling system to connect wagons and railcars, the European freight industry still uses a universal screw system. Result: coupling/decoupling operations are longer, more frequent and more taxing for workers.

Brake testing made easy

With today’s universal screw system, coupling, decoupling and checking wagons takes a lot of walking, and operators must test the train’s brakes by releasing air from the brake pipe and kicking each brake block. With an automated coupling system, workers’ tasks are streamlined and reduced, and they can simply monitor the process from the drivers’ cab.

The key to modernization

DAC makes workers safer and more efficient—and those aren’t the only benefits. It’s one of many innovations now being developed by European working groups to harmonize the continent’s rail system.

Double rail traffic by 2030

With DAC, freight trains can be longer and heavier because they can generate vital train integrity data. That’s why this technology is integral to the European Green Deal2. Deploying and funding DAC at European level will require major investments to strengthen rail freight’s business model and make it more competitive with road transport.

Q&A with Aurélie Bigey and Antoine Rothey

How is DAC different?

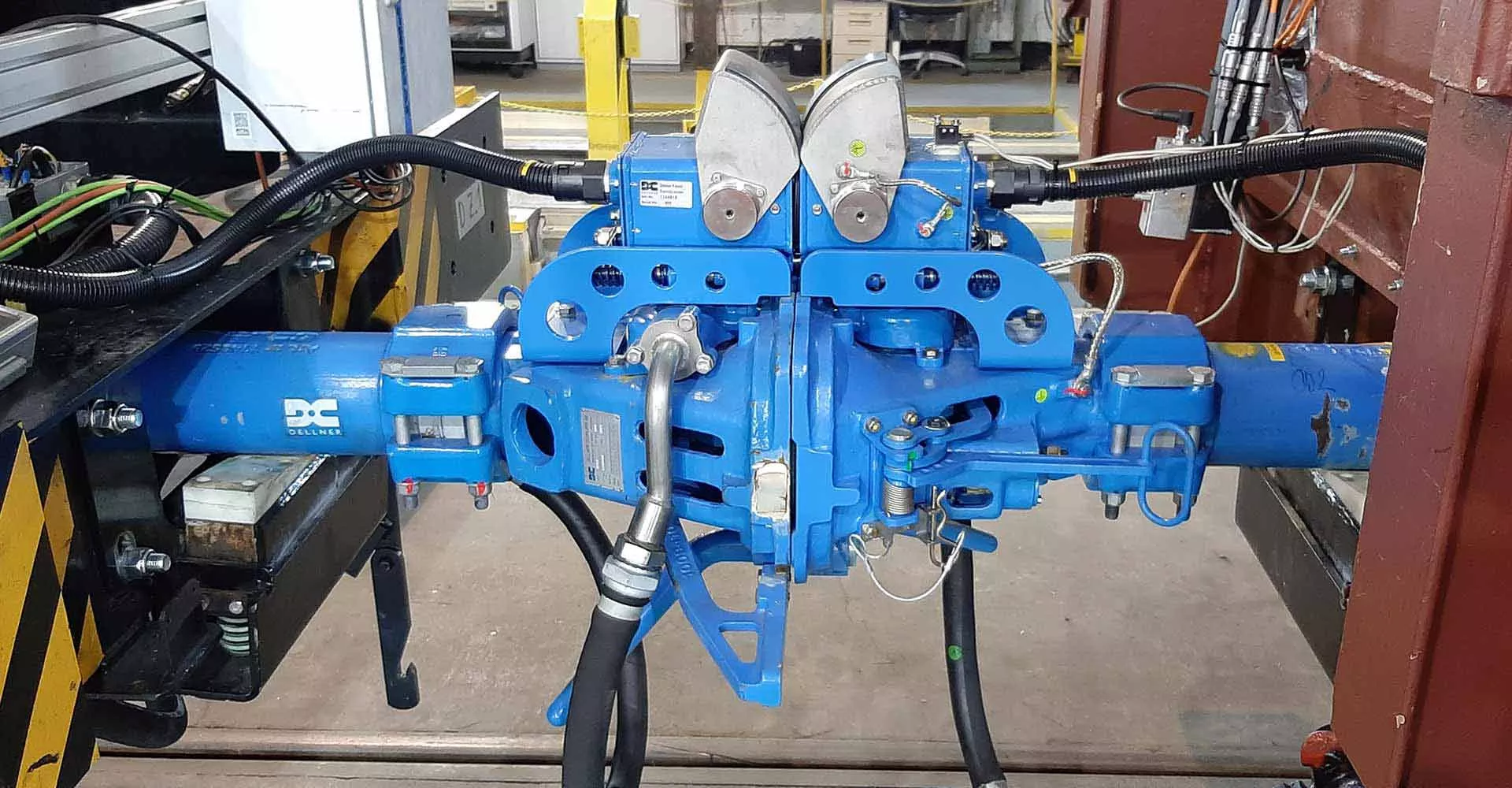

DAC has a mechanical component, a pneumatic component, an electrical component and a data communication component. The pneumatic connection ensures braking continuity in all of the wagons, and DAC also provides for connection of the electrical and data systems. When they’re disconnected, flaps close to protect the components from dirt and dust.

What makes DAC digital?

With DAC, freight trains are digitally connected, and that allows for a wide range of functions. We can monitor each wagon’s components, such as brakes, wheels, air continuity, and load positioning. We can also monitor train integrity, which is really useful for tomorrow’s signalling systems, for sending alerts to the driver, and more. In short, we have a lot more control thanks to data from sensors on the wagons. And in addition to its value for train maintenance, DAC provides live data to the driver.

Will DAC be installed on all wagons?

Yes. They’ll all go through ‘DACcination centres’. For that to work, we’ll need to be able share data throughout the sector. Today, every wagon keeper knows where its own wagons are, but we still need to find a way to share that localization data with the owner, the rail operator, and the other players. That’s exactly what our Digital Platform project is working on, and it’s a big investment. The most important thing is to make sure customers don’t suffer. They’ll need the wagons during the transition to DAC.

How will it work?

We’re planning a 2-step transition to DAC. The first step will be mechanical: we’ll pre-install draft gear under the wagon in a workshop. That lets us continue to use the screw coupler. The second step is the Big Bang: in a 2-week, on-site process, we’ll replace the screw couplers with DAC heads on all of the wagons previously fitted with draft gear. It’s an ambitious plan, so all of the players need to be involved.

Reaching compromise

EU member countries don’t operate every wagon the same way, and industry players—manufacturers, lessees, infrastructure managers, and operators like SNCF—don’t have the same needs and requirements.

To develop the technical specifications for DAC, all the players in European rail are working together, seeking compromises that will satisfy the full range of stakeholders.

Countdown to 2025

The goal of the European programme is to have a type 53 coupler operational, tested, validated and authorized by the end of 2025. We’ll also draft the standards we need to use DAC on every train in Europe. One part will come from industrial standards, and another will be defined as part of the technical specifications for interoperability.

Europe’s Rail

To support research and innovation, the European Union is forging partnerships with EU industrial companies, on the premise that every euro spent by the European Commission will be matched by the companies. The partnerships are set for 6-7 years to track the funding timeline for European budgets. In all, Europe’s Rail represents investments of around €1.2 billion.

A freight revolution

Modernizing the freight industry means developing a wide range of technologies at the same time. To revolutionize the sector, we’ll need a combination of innovative breakthroughs.