From TGV M to the new TGV INOUI

On track to launch from 2026, the new 5th-generation TGV is modular, 97% recycled and energy efficient. Join us for a deep dive into this distillation of cutting-edge technologies for high-speed travel in France and Europe, including features, design, innovations and services.

Fine-tune your content

Short version

No train has ever logged so many kilometres in test phase

The new TGV INOUI set a record even before entering commercial service, travelling 1 million km in 350 weeks of testing—more than any train in trial phase. A striking figure that reflects the sheer scale of the project, launched when SNCF placed a €3.5bn order for 115 trainsets with Alstom in 2018.

TGV M

Modular, modern and mastery are features built into this 5ᵗʰ-generation TGV—TGV M.

M for modularity

The new TGV INOUI has more capacity: 9 coaches—up from 8—boost seats on board by 20%, to a maximum 740. And trainsets are themselves modular: interiors can be reconfigured, with 1st class coaches converted to 2nd and vice versa. Luggage racks and bike spaces (8 in all) are also adjustable.

M for mastery

A full 100 tonnes of materials are recycled—25% of the total—giving this high-speed train the lowest carbon footprint on the market. Its sleek composite nose has been redesigned for enhanced aerodynamic performance, making it 20% more energy-efficient than the prior generation. Together these breakthrough technologies reduce CO2 emissions by 50% compared with single-deck TGVs.

M for “Made in France”

The new TGV is entirely designed and assembled in France, with contributions from 11 of Alstom’s 16 plants representing 4,000 rail sector jobs.

100% connected

On-board WiFi architecture complies with the latest 5G standards to deliver an outstanding travel experience, including access to connected services for passengers, with full real-time connectivity in each carriage.

97%

of materials in the new TGV INOUI are recyclable

100%

French design

20%

more seats on board

High-speed rail travel

This 5ᵗʰ-generation TGV mobilized over 2,000 contributors in industrial processes pioneered under the Alstom/SNCF Voyageurs partnership.

All-new framework for an innovation-driven partnership

As the 5th-generation TGV, TGV M is backed by ADEME, France’s environment and energy management agency, and SGPI, the country’s General Secretariat for Investment. Since its launch in 2016, it has tapped into top-tier industry expertise at Alstom and SNCF Voyageurs, who joined forces on a single platform in an unprecedented partnership powered by innovation.

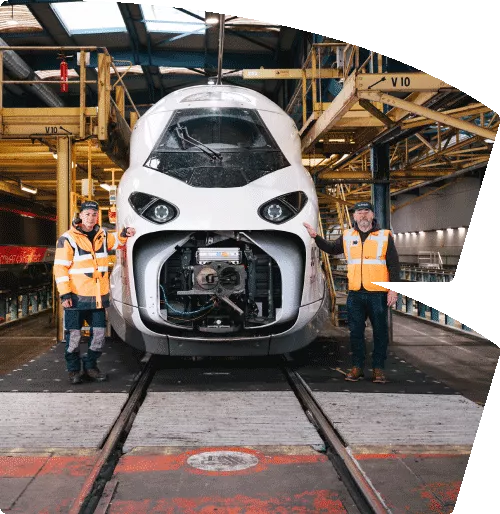

Expert maintenance by SNCF Voyageurs

SNCF Voyageurs has launched a major effort to update its maintenance centres for the new TGV INOUI. This started with the upgrades to the Southeast Europe Technicentre (TSEE), whose 850 employees already service nearly one-quarter of the TGVs serving France, Italy, Switzerland, Spain and Germany. From 2023 on, SNCF Voyageurs is investing €300 million to update the TSEE, setting the standard for next-generation SNCF Voyageurs Technicentres that are more modern, more connected and more eco-friendly—like the TGV M itself.

All-new industrial processes at Alstom

Altogether 11 Alstom plants in France have contributed to the project, including a new locomotive production line in Belfort and a new assembly line for coaches in La Rochelle. Alstom also introduced innovations in functional validation for door operation, air conditioning and more, by creating a virtual digital twin of the new TGV at its TrainLab test laboratory.

Over 400 innovations, including a world first

The TGV M project is a distillation of cutting-edge technology, with over 400 innovations. These include a world first: the “graft”, a revolutionary battery that lets trains continue to operate even when main power fails. This emergency solution uses backup batteries that can power trains to the nearest station, keeping traffic running smoothly even after a breakdown.

1 Million

km logged during trials leading up to commercial operation

115

SNCF Voyageurs has ordered 115 trainsets from Alstom for €3.5bn

2,000

people contributed to the TGV M projet

Sleek, timeless design

Created by our multidisciplinary agency AREP and Japanese designers at Nendo, the train’s exterior blends seamlessly into the environment. Interiors were created to meet the needs of passengers, train managers and drivers.

Exteriors break with tradition

The new TGV’s redesigned nose features an extended black ellipse for a new look. More aerodynamic, it also offers significant energy savings. Sober livery adds a note of elegance, and tougher exterior paint has greater reflective power, limiting energy consumption in hot weather.

Meeting everyone’s needs

For the first time in TGV’s history, all crew members—train managers, drivers, technicians, maintenance staff and more—were consulted on interior features. Virtual reality tools helped create an optimized driver’s cabin and a coach dedicated to wheelchair-bound passengers. Seats use a 3D woven fabric, with 85% wool fibre and a useful life estimated at 30 years. Innovative foam was tested on 125 body types for greater passenger comfort, while onboard toilets were revisited and expanded. Last but not least, 3 bike spaces are available in each trainset, and up to 8 non-dismantled bikes can be carried board.

Explore the new TGV INOUI’s driver’s cabin

Bistro replaces café-restaurant

A core feature of the new train design is Le Bistro, replacing café-bars in earlier models. Positioned in coach 4, this occupies both upper and lower levels, with a staircase linking the two. Customers purchase refreshments on the lower level, at a convenience store and self-service fridges. They pay at automated terminals, with baristas on hand to help out. The bright, airy upper level is welcoming, with 28 seats and room for more clients standing.

20%

more luggage space than on 4th-generation TGVs

8

places for bicycles (not dismantled)

90%

of seat materials are recyclable

Project milestones

Share the article