FLEXY—the road-rail system for small local lines

An electric shuttle that can travel on both road and rail? It’s coming soon with FLEXY, the brainchild of a consortium1 led by SNCF. Agile, economical, and decarbonized, this hybrid system is the mobility solution for small communities.

Today, the French rail network has some 5,700 km of disused line, most of it single-track. The FLEXY system aims to revitalize these small lines by offering a decarbonized, shared alternative to privately owned cars, especially in rural and suburban communities. This new mobility solution is designed for 30-km segments of line with at least 5 stations and potential ridership averaging 300-500 passengers a day.

Reviving small local lines with the FLEXY road-rail transport system

1 system, 4 components

The FLEXY system is being developed by a 4-member industrial consortium—SNCF, Michelin, Milla Group and the Railenium research institute—with support from France’s Brittany and Burgundy-Franche-Comté regions. Slated to enter commercial service by 2028, FLEXY has 4 components:

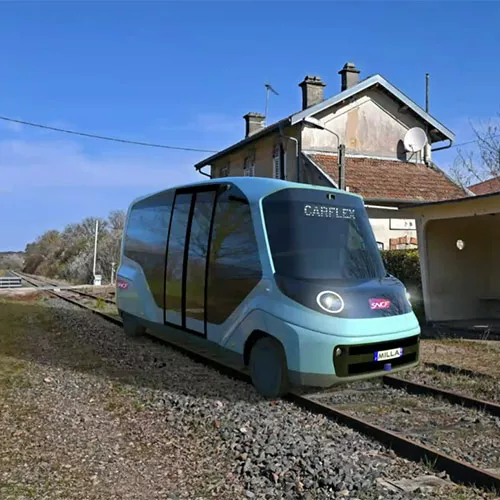

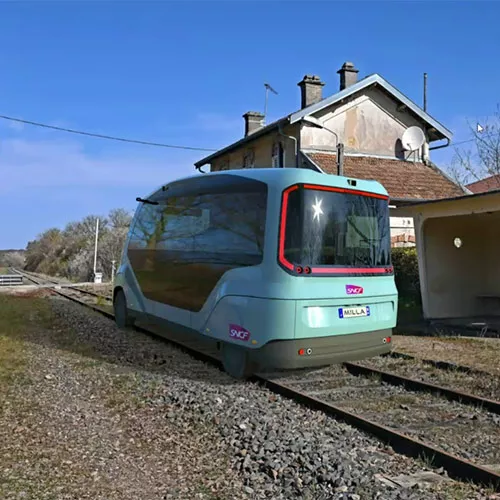

- Carflex, a hybrid road-rail electric shuttle

- streamlined infrastructure and maintenance

- specially-designed operating and control systems

- special regulations

12

The Carflex shuttle has 14 seats

200km

This battery-powered electric shuttle has a 200-km range

36

months of work from preliminary design to commercial authorization

Combining road and rail with Carflex

The Carflex shuttle is based on a Renault Master commercial vehicle with a modified chassis to accommodate dual-function wheels, and is powered by electric batteries giving it a range of 200 km.

Patented by Michelin

The biggest innovation is that Carflex can run on both rail and road thanks to dual-purpose wheels, specially designed in partnership with Michelin. “With these wheels, we can deliver road service to communities near the tracks, travel through level crossings that have been converted into road intersections, and boost service on single-track lines by creating passing zones,” says Nathalie Peignet, FLEXY Project Leader, within the SNCF Tech4Mobility programme2.

Adapting to local needs

Carflex is accessible for people with limited mobility, and can contain up to 12 seats. But the modular interior can also be reconfigured to carry bicycles and micro-freight.

Streamlined infrastructure

The FLEXY system cuts the cost of reinvestment in disused lines. “We’ll remove trackside components—such as signalling for heavy trains and switching equipment—to accommodate the dual-purpose wheels,” says Nathalie Peignet.

Smart, cost-effective platforms

FLEXY’s infrastructure includes 3 types of smart, cost-saving platform. Transition platforms let the shuttle shift from road to rail, and vice versa. Intersection platforms allow Carflex to switch to road mode in places where old level crossings have become crossroads. And passing platforms boost service frequency on single-track lines by letting 2 shuttles pass each other.

Lower maintenance costs

Infrastructure maintenance costs are significantly lower for FLEXY lines, which have no level crossings or switches. Stations and light passenger platforms are the only equipment they need.

Innovative operating system

The FLEXY project includes a digitalized control system to manage the biggest railway risks, such as rear-end collisions, head-on collisions, and obstacles. At transition platforms, the shuttle’s wheels will be rerailed automatically to ensure safe operation and keep Carflex moving at rated speed as it shifts back onto the rail line.

70 km/h by rail, 80 km/h by road

The Carflex shuttle is designed to run at a minimum speed of 70 km/h by rail and 80 km/h by road—subject to local speed limits, of course. This level of performance will help keep the FLEXY system competitive with coaches and privately owned cars. In addition, rail lines are straighter and more direct than roads, and trains are unencumbered by the restrictions of road traffic.

Special regulations

As a hybrid, the FLEXY project must meet the requirements for both road and rail, and it needs a special set of regulations to run on the rail network. We’re now working on this in talks with the French Railway Safety Authority (EPSF) and the STRMTG, France’s national safety agency for ropeways and guided transport.

Certification in 2028

Carflex will run on dedicated lines that won’t be shared by any other type of railway rolling stock, and it will be monitored by driver-assistance systems when it passes other shuttles and travels through road-rail intersections. We plan to hold a system safety demonstration for French regulatory authorities in 2028 as part of the certification process.

Testing Carflex behaviour in Brittany and Burgundy-Franche-Comté

In 2023, the SNCF Tech4Mobility team ran trials on a closed segment of rail line between Rosporden and Concarneau in south-western Brittany. They used a testbed vehicle called a mule3 to assess the vehicle’s ability to enter the system’s road-rail transition platforms. Also present were representatives of the Centre for Rolling Stock Engineering (CIM), SFERIS (an SNCF Réseau subsidiary), the French Railway Test Agency (AEF), and FLEXY project partners Milla Group, Michelin and Railenium.

Another closed rail segment, this time between Autun and Etang-sur-Arroux in Burgundy-Franche-Comté, will host validation trials of the FLEXY system starting at the end of 2026.